-

Technical Research and Development

Our company has jointly carried out scientific research projects together with Liaocheng University and North China Electric Power University, and possesses a professional experimental base and a RD team. Based on existing resources, we carry our cooperations in scientific research to promote the commercialization of research outcomes. We also have obtained 32 national patents in steel silo structure safety, steel silo output rate, the discharge device for large steel silos, and environmentally-friendly warehousing.

Owning independent intellectual property rights, we are the leader in the technical development, application and construction of multi-point and multi-lane discharge of steel silos. Yuanfeng features a sophisticated technical service system, and hence can provide customers with power technical support.

-

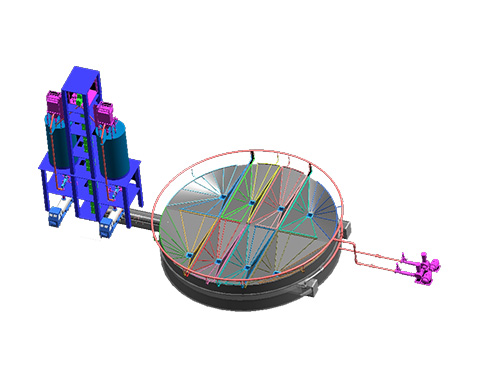

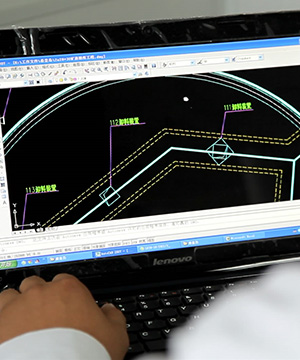

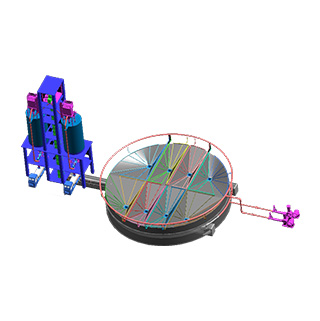

Consultation & Design

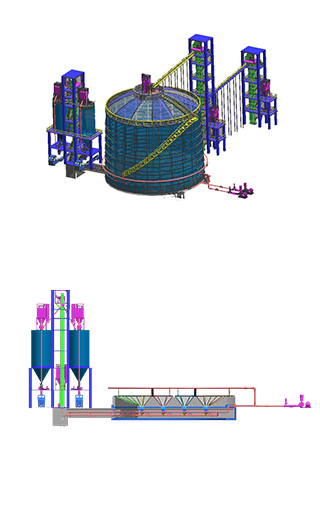

At present, there are 46 professional designers in the company, including process engineers, structural engineers, electrical engineers, thermal control engineers, water supply and drainage engineers, etc. Yuanfeng has established a long-term and stable cooperative relationship with many construction companies and class A construction design institutions in Shandong Province. The company can undertake activities including the planning, feasibility study, preliminary design, construction drawing design, technical service for the cement conveying and storage on domestic and overseas cement production lines, clinker storage, conveying and storage on aggregate production lines, fly ash conveying, transferring and storage in the power industry. It is capable of designing the whole business chain from the output to the loading, sorting and processing of fly ash, cement, aggregate, clinker, mineral powder, coke and other granular materials.

Based on the intelligent Internet of Things and the industrial cloud platform, our company adopts an intelligent warehousing operation and maintenance system to collect the full information of steel silos. The client terminal on computer and mobile phone allows for operation status diagnosis and maintenance; real-time monitoring of energy consumption; data collection and analysis; centralized management of incoming and outgoing materials in the warehouse.

-

Procurement

The company specializes in the equipment procurement business in power, cement, aggregate, clinker, steel, electrical and other industries, covering procurement, manufacturing supervision, inspection, reminder, transportation and so on. Yuanfeng boasts a professional procurement team and a well-developed procurement quality system to ensure reasonable EPC material procurement arrangement and resource allocation. It maintains sound business relations with hundreds of competent equipment suppliers by means of procurement progress control, material procurement bidding, and negotiation management, and carries out procurement by fully utilizing the RD and design resources of Yuanfeng.

The company signs supply and service contracts at a reasonable price, and is able to complete production supervision, delivery reminder, logistics and transportation, installation and commissioning, acceptance, document handover, as well as the receipt, distribution and storage of all materials needed in steel silo works in a quality and efficient manner, so as to catch up with the work progress. It can guarantee that the products offered meet the requirements of large steel silo constructors, thus eventually securing the work quality and progress, and protecting the interests of steel silo constructors to the maximum extent.

-

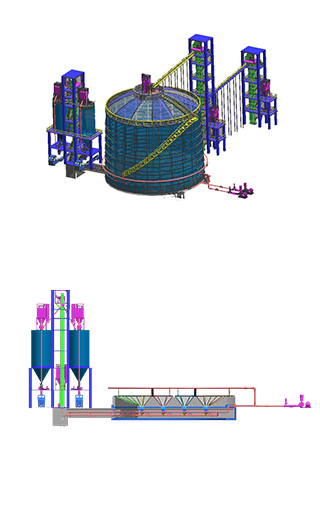

Sub-work Construction

The construction procedure of steel silos is divided into civil foundation, steel structure construction, equipment gasification installation, electrical installation and commissioning. All sections proceed in an alternate way so that the progress is guaranteed.

① - Positioning

② - Foundation excavation

③ - Formwork binding

④ - Concrete pouring

⑤ - Silo roof fabrication and installation

⑥ - Silo body fabrication and installation

⑦ - Silo body de-rusting and anti-corrosion treatment

⑧ - Masonry construction in the silo

⑨ - Gasification installation

⑩ - Discharge installation

⑪ - Electrical automation installation

⑫ - Steel silo completion

-

Project Management

The smart application of steel silos based on the Internet of Things, the intelligentization, and the Internet deeply combines Internet of Things, cloud computing, big data, mobile Internet technologies with the construction and operation of steel silos. The purpose is to make steel silos more energy-efficient, greener, and safer. The company now owns 17 project management agencies, 8 grade I certified constructors and 20 grade II certified constructors. By applying a management mode focusing on steel silo works, Yuanfeng installs and inspects all the equipment needed for the construction of steel silos in strict accordance with drawings and technical requirements. It can also effectively control the progress, quality, safety, and cost of each steel silo work by virtue of the network-based visual management of steel silo works and the close collaboration of EPC, and therefore maximize the value for customers.

The company now owns 17 project management agencies, 8 grade I certified constructors and 20 grade II certified constructors. By applying a management mode focusing on steel silo works, Yuanfeng installs and inspects all the equipment needed for the construction of steel silos in strict accordance with drawings and technical requirements. It can also effectively control the progress, quality, safety, and cost of each steel silo work by virtue of the network-based visual management of steel silo works and the close collaboration of EPC, and therefore maximize the value for customers.

-

After-sale Service

After our products are delivered, we will complete the Customer Profile and maintain quarterly return visits. The product quality is covered by PICC insurance. Yuanfeng guarantees to carry out construction in strict accordance with current national regulations, keep close cooperation with owners, and provide life-long follow-up services for customers. Our steel silos have a designed service life of 30 years. We promise that:

1. We will establish customer profiles, maintain computer-based systematic management, keep us informed of customers’ comments on product quality, performance, after-sale service by means of phone calls, correspondences, and door-to-door visits according to different use durations of products, and solve problems for customers.

2. We will provide 1-year free maintenance for the equipment, materials, and components purchased by customers for the work, except wearing parts, on the condition that the equipment operates properly.

3. We will send special construction teams, and our construction personnel are labeled and receive supervision.

4. We will obey the management by the owner and the supervisor and will maintain close cooperation with other teams

5. After the completion, we will complete the installation and commissioning within the given time according to the requirement of the employer.

6. After the work is accepted, we will provide free technical training for customers, which covers equipment operation procedure, routine repair, preventive repair, fault setup and other maintenance procedures.

7. We will value the feedback of customers and accept their complaints.

8. Our repairs will arrive at the site of any system failure within 3 working days.

9. We offer one-year warranty period under normal operation

10. The works undertaken by our company are insured by PICC.